- MELT BLOWN

- Characteristics of Facilities and Products

- Air Filter

- Liquid Filter

- Mask & Respirator

- TPU

MELT BLOWN

· Melt-blown nonwoven fabric is a nonwoven fabric manufacturing method that melts thermoplastic polymers such as PP (polypropylene) and extrudes them through a nozzle.

· After the melted polymer is transferred to the metering pump through the extruder, each polymer passes through a distribution plate. Here, the crucial step is the application of high temperature and high-pressure air to the melted polymer through a nozzle. This process stretches and fines the polymer, preparing it for the next step. The polymer is then laminated on a conveyor belt and bonded with self-adhesion to manufacture a nonwoven fabric.

· After the melted polymer is transferred to the metering pump through the extruder, each polymer passes through a distribution plate. Here, the crucial step is the application of high temperature and high-pressure air to the melted polymer through a nozzle. This process stretches and fines the polymer, preparing it for the next step. The polymer is then laminated on a conveyor belt and bonded with self-adhesion to manufacture a nonwoven fabric.

Characteristics of Facilities and Products

· We have composite spinning equipment capable of producing nanofibers of the 800 nm (0.8 ㎛) level.

· Our pilot equipment is not limited to a single type of resin. It can test the production of various thermoplastic resins, including PP, PA, PET, PBT, TPU, and more.

· We can produce high-efficiency, low-composition filter products such as air filters, water treatment filters, and masks.

· Our pilot equipment is not limited to a single type of resin. It can test the production of various thermoplastic resins, including PP, PA, PET, PBT, TPU, and more.

· We can produce high-efficiency, low-composition filter products such as air filters, water treatment filters, and masks.

Air Filter

· For HEPA filters filter 99.97% of ultra-fine dust of 0.3㎛ and implement the same filtration efficiency with 1/3 the differential pressure compared to existing glass filters through the electrostatic filtration method.

· Production of H10-H14 Grade filters (EN1822 standard)

· Production of H10-H14 Grade filters (EN1822 standard)

| Filter Grade | Standard Spec. | MB Weight (g/㎡) | Pressure Drop (mmAq) |

|---|---|---|---|

| H-10 | 85% | 20 | 0.7 |

| H-11 | 95% | 20 | 1.2 |

| H-12 | 99.5% | 20 | 2.0 |

| H-13 | 99.95% | 30 | 3.0 |

| H-14 | 99.99% | 35 | 3.5 |

Measurement Instrument : TSI 8130, Flow Rate : 32LPM,

Particle Size : 0.3 micron, Test Particle : NaCl

Particle Size : 0.3 micron, Test Particle : NaCl

Liquid Filter

· Removes contaminants from industrial water used in food and beverage, chemical, and semiconductor industries

· Excellent uniformity due to uniform yarn thickness

· Various grades of products available: Pore size (1~80㎛)

· Can be used as sub-media for membrane filters

· Excellent uniformity due to uniform yarn thickness

· Various grades of products available: Pore size (1~80㎛)

· Can be used as sub-media for membrane filters

| Filter Grade | Basis Weight | Air Permeability | Width | Remark |

|---|---|---|---|---|

| 1㎛ | 120GSM | 0.1 cm3/cm2/sec ↑ | Max. 150cm |

Calender |

| 2㎛ | 120GSM | 0.1 cm3/cm2/sec ↑ | ||

| 3㎛ | 60GSM | 0.7 cm3/cm2/sec ↑ | ||

| 4㎛ | 40GSM | 1.0 cm3/cm2/sec ↑ | ||

| 6㎛ | 30GSM | 5.0 cm3/cm2/sec ↑ | Un-calender | |

| 6㎛ | 60GSM | 6.0 cm3/cm2/sec ↑ | ||

| 10㎛ | 55GSM | 10 cm3/cm2/sec ↑ | ||

| 20㎛ | 50GSM | 28 cm3/cm2/sec ↑ | ||

| 35㎛ | 75GSM | 40 cm3/cm2/sec ↑ | ||

| 80㎛ | 60GSM | 128 cm3/cm2/sec ↑ |

· Measuring Equipment : Capillary Flow Porometer, CFP-1100A

· Wetting Liquid : Galwick

· Material : Polypropylene

Mask & Respirator

· Used as a core filter layer for quarantine and medical masks, as well as industrial dust masks

· Used as an alternative material for 3M masks as a product with low inhalation resistance for dust masks

· Used as an alternative material for 3M masks as a product with low inhalation resistance for dust masks

| Division | MB Basic Weight (g/㎡) | Filtration Efficiency (%) | Pressure Loss (mmAq) | Test Method |

|---|---|---|---|---|

| BFE 95 | 20 | 85 | 2.2 | NaCl, 32L/min |

| BFE 99 | 22 | 90 | 2.5 | NaCl, 32L/min |

| N95 | 30 | 95 | 11.0 | NaCl, 85L/min |

| N99 | 40 | 99 | 13.0 | NaCl, 85L/min |

| (Dustproof 1st class) , FFP2 | 40 | 94 | 15.0 / 12.0 | Paraffin Oil, 95L/min |

| (Dustproof 2nd class) , FFP1 | 30 | 80 | 13.0 / 9.0 | Paraffin Oil, 95L/min |

| KF94 | 40 | 94 | 14.0 | Paraffin Oil, 95L/min |

| KF80 | 30 | 80 | 12.0 | Paraffin Oil, 95L/min |

Measurement Instrument : TSI 8130, Particle Size : 0.3 micron

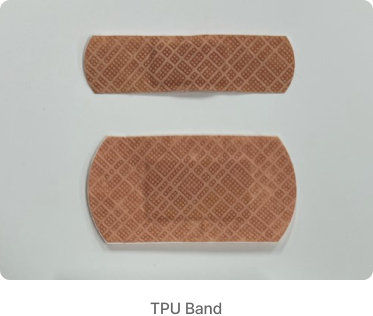

TPU

· Nonwoven fabric produced by the melt-blown process of high-elasticity urethane series

· Excellent tensile and tear strength

· Excellent rebound elasticity and elastic recovery force, allowing continuous use

· Excellent environmental and human-friendly properties compared to PVC materials

· Consisting of fine fibers, it has excellent breathability and is friendly to the skin

· Excellent tensile and tear strength

· Excellent rebound elasticity and elastic recovery force, allowing continuous use

· Excellent environmental and human-friendly properties compared to PVC materials

· Consisting of fine fibers, it has excellent breathability and is friendly to the skin

| Grade | MB Weight (g/㎡) | Thickness (mm) | Color |

|---|---|---|---|

| MF0075EU | 75 | 0.22 | White & Skin |

| MF0085EU | 85 | 0.30 | White & Skin |

| MF0100EU | 100 | 0.49 | White & Skin |

Welcron Mall

Welcron Mall Sesaliving Mall

Sesaliving Mall